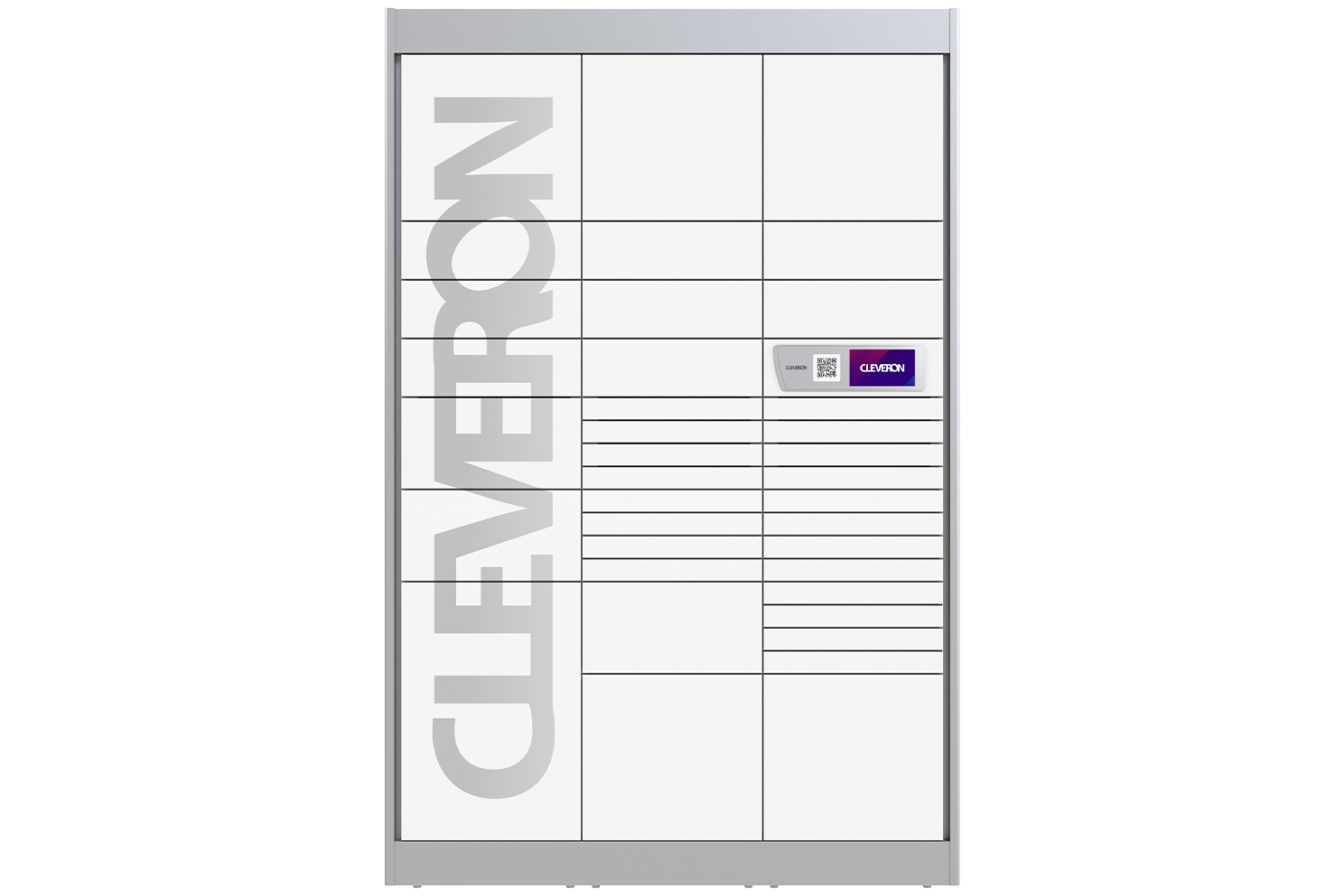

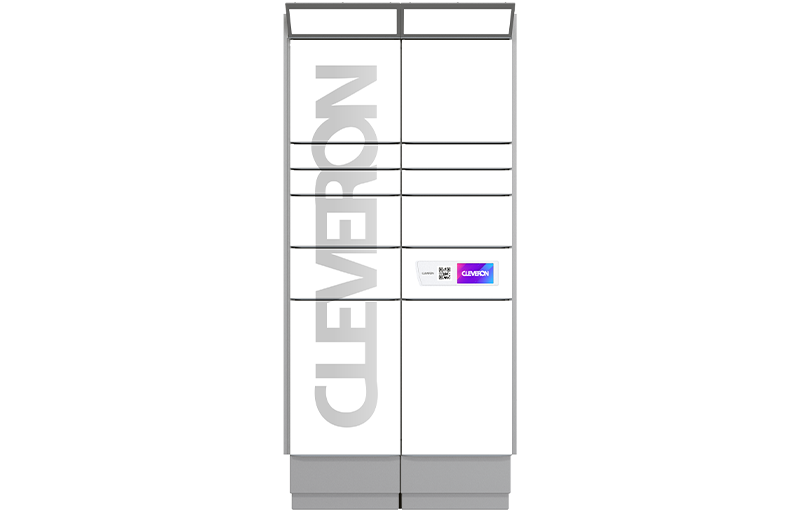

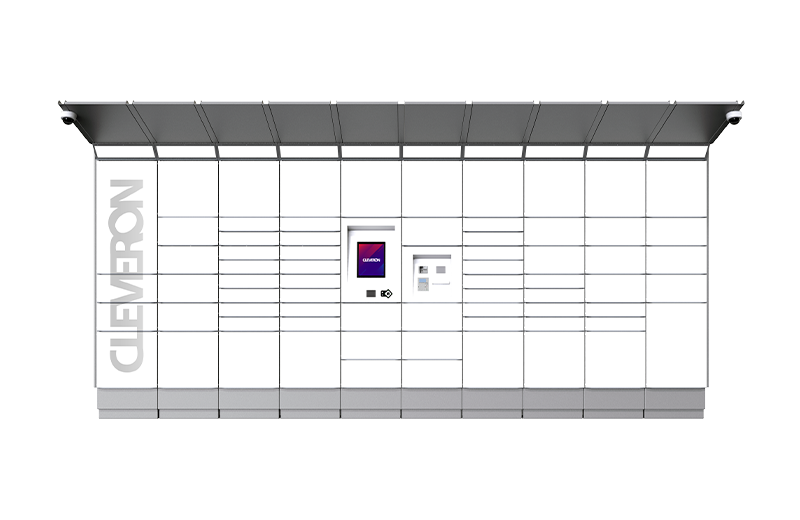

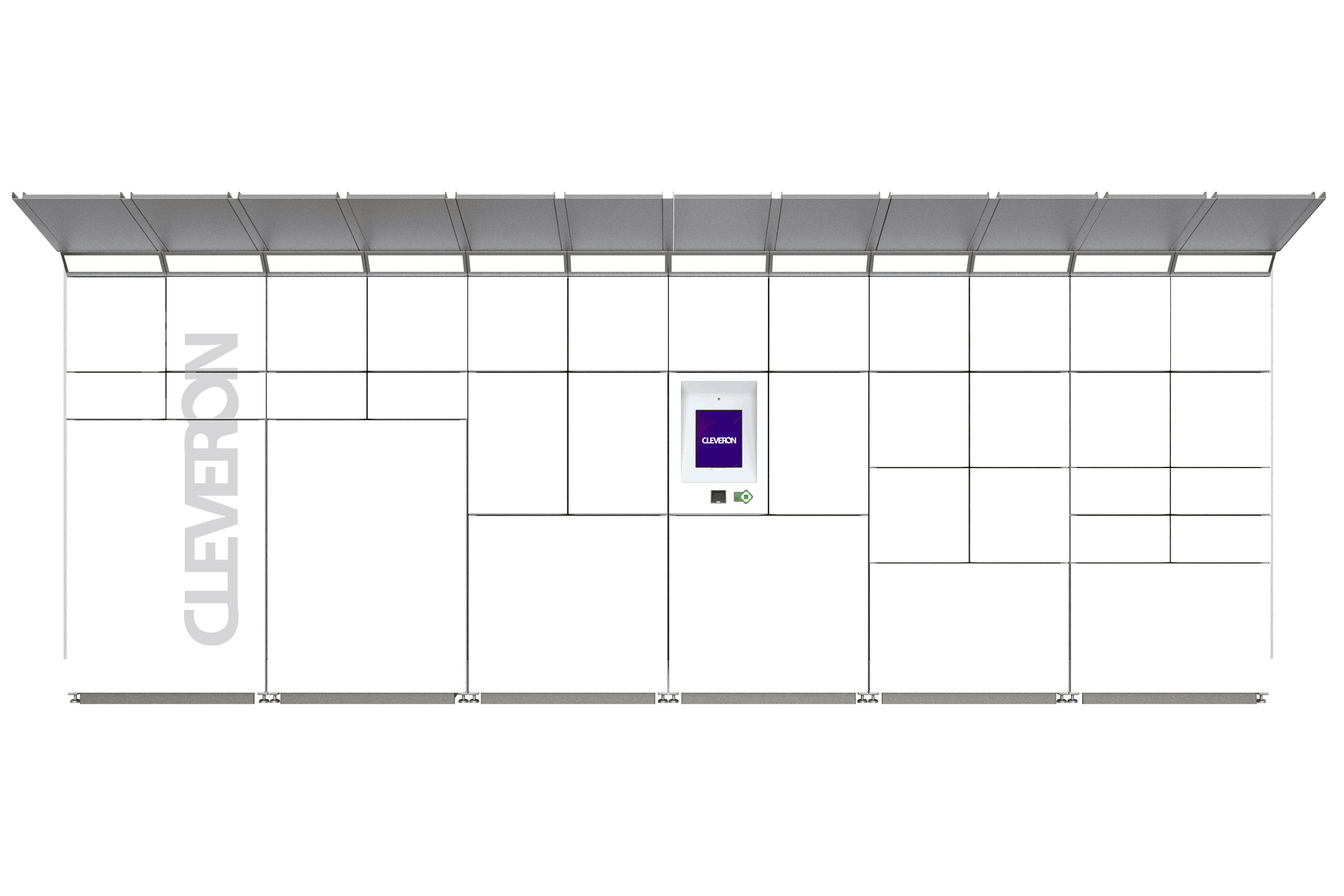

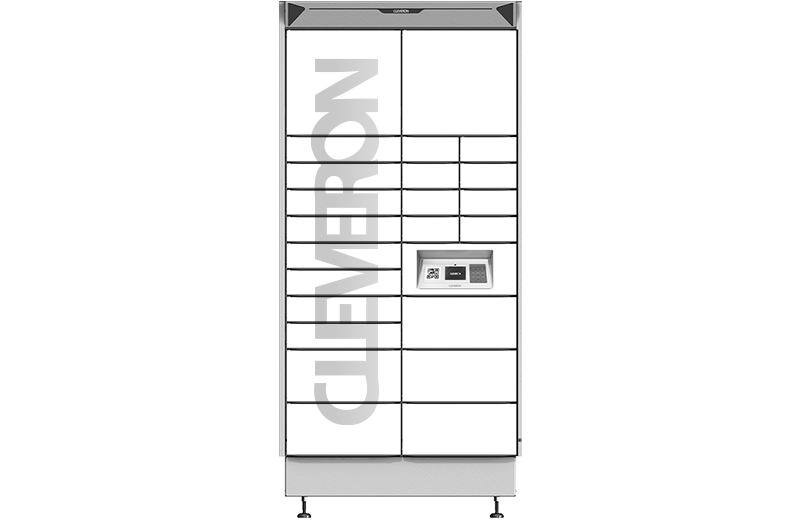

We are launching an upgraded version of Cleveron 403, focusing on improving the configuration for better space optimisation and redefining the future of retail technology and click-and-collect services.

Last-mile innovation remains critical to staying ahead of the curve in a world driven by ever-evolving consumer demands. At Cleveron, we believe in creating solutions that meet today’s needs and anticipate tomorrow’s requirements. The journey to developing the Cleveron 403’s new version was a testament to this philosophy – a process characterised by ingenuity, collaboration, and relentless pursuit of excellence. Here’s an inside look at how this groundbreaking version came to life.

Redefining Priorities: Why launch a new version?

The Cleveron 403 has always stood as a robust solution for parcel automation. However, the growing demands of industries like retail and logistics called for a more innovative, faster, and adaptable product. While the earlier iterations set high standards, we saw an opportunity to fine-tune the user experience, optimise their space better and address key customer pain points such as insertion speed, space efficiency, and energy consumption. In this version, our mission was clear: we aimed to maximise space utilisation in terms of the footprint the Cleveron 403 occupies in the store and the efficient arrangement of parcel trays inside the locker to enhance operational efficiency.

Streamlining the Insertion Process

One of the standout improvements in the new Cleveron 403 lies in its reimagined insertion process. By reducing insertion times by up to 30%, we’ve significantly enhanced throughput, saving precious seconds for both the couriers and retailers. This improvement stems from integrating the fast-loading mechanisms, which we were the first to launch and feature in our other robotic parcel locker, Cleveron 402. By eliminating the need for manual confirmations after package insertion, parcels now “fly” seamlessly into the system, revolutionising speed without sacrificing reliability. Our testing processes ensured that the Cleveron 403 is ready for fast loading, and scientifically tested with real-life packages. This also enhanced our ability to detect oversized parcels.

The insertion process was further optimised through mechanical advancements and software refinements. These changes allowed us to streamline every interaction, ensuring that end users experience effortless operation while businesses reap the benefits of improved efficiency.

Maximising Space Utilisation

In today’s retail landscape, real estate is at a premium. This version’s innovative approach to surface area efficiency is a key differentiator. We reduced the overall service area by redesigning the system’s internal structure and introducing a new height(3.6m) for Cleveron 403 while increasing storage capacity. The result? A higher parcel volume in the same footprint. This improvement enhances operational KPIs and makes Cleveron 403 an attractive option for businesses looking to maximise return on investment on their available space.

The reduced service area also has practical implications for maintenance. With a more compact and intuitive design, routine servicing requires less space and time, allowing businesses to focus on operations with minimal interruptions.

Cutting-edge technology at its best

Technology upgrades are at the heart of Cleveron 403’s success. One of the most notable additions is the console camera, which unlocks new machine learning and security possibilities. This camera enables the system to analyse parcel behaviour during storage and retrieval, paving the way for smarter operations and enhanced oversight. It also serves as a strong security measure, recording what is placed on or removed from trays, ensuring accountability and peace of mind.

Another leap forward was the introduction of an electric motor, which upgraded the mechanical assembly to a motor-driven system for opening the console door. The door material was also changed from plastic to bright glass, further enhancing both functionality and aesthetics. With an enhanced parcel measurement system, the upgraded Cleveron 403 establishes new standards for accuracy and flexibility.

Sustainability: A Step Forward

Sustainability was a fundamental consideration during the design of the new version. The system’s enhanced energy efficiency, achieved via optimised mechanics and streamlined operations, helps businesses lower their carbon footprint. Additionally, using durable and long-lasting components reduces waste throughout the product’s lifecycle. Although not every sustainable development initiative reached full implementation, the foundation laid by the development of this version will guide our future advancements in sustainable design.

Thorough Testing for Quality Assurance

Developing a product like the Cleveron 403’s new version demands rigorous testing to meet the highest standards of performance and durability. Throughout the development process, we decisively replaced traditional testing methods with innovative approaches that effectively simulate real-world scenarios. For instance, we programmed automated tests to mimic years of usage in just a few months, inserting and retrieving thousands of parcels under various conditions. By doing so, we significantly shortened the development timeline without compromising on quality.

We conducted crash tests, checked for oversized parcels, and measured sound levels. These tests ensured that the Cleveron 403 could handle the real-world challenges our customers face, including high parcel volumes and rare accidents during operation.

Collaboration: The Backbone of Success

The journey to the new version was not without its challenges. We embarked on the development of the new version of Cleveron 403 with limited resources, and collaboration became the cornerstone of our success. Engineers, software developers, and product managers worked together to overcome obstacles, often stepping outside of their traditional roles to support one another.

A key example of this collaboration is the creation of our ticketing and documentation systems. These tools enabled us to track real-time hardware changes, software updates, and customer feedback, ensuring no detail was overlooked. The team’s ability to adapt and innovate under pressure is a testament to the culture of resilience and creativity that defines Cleveron.

Lessons Learned and the Road Ahead

The development of Cleveron 403 Version 4 was as much about learning as it was about building. Key takeaways from this process include:

- Double the Buffer: Always allocate extra time and resources during the planning phase to account for unforeseen challenges.

- Customer-Centric Design: Early engagement often provides invaluable insights guiding meaningful innovation.

- The Power of the Team: A motivated and strong team can achieve outstanding results even in difficult situations.

These lessons will inform future projects as we continue to push the boundaries of what’s possible in parcel automation.

Three words to define the new version

If we had to encapsulate the new Cleveron 403 in three words, they would be:

- Reliable: Designed to deliver optimal performance in any indoor store environment, ensuring reliable results every time.

- Efficient: Designed for speed and space optimisation, maximising value for businesses. We travelled to customer locations to see the best possible dimensions for space optimisation.

- Economical: The new version is designed to save on cost per square foot, making it an economical

The Cleveron 403’s new version is a reflection of our commitment to innovation, collaboration, and customer success. As it enters the market, we’re excited to see how it transforms operations for businesses around the world. The future of parcel automation is here, and it’s more promising than ever.