Discover how we prepare to help retailers and logistics partners counter Black Friday chaos with automation, resilience, and data-driven logistics.

Black Friday and the holiday rush are defined by market volatility and massive, sudden spikes, making them feel completely unpredictable. A single product going viral on social media, for instance, can jump sales from 0 to 10,000 in a matter of hours.

For retailers and logistics networks, this unpredictability is the ultimate stress test, where speed, scale, and customer experience collide.

Your employees are the lifeblood of your store, but when they’re swamped manually sorting, storing, and handing over parcels, two things happen:

- In-store experience crumbles: Manual parcel handling becomes a massive disturbance to in-store sales and customer service.

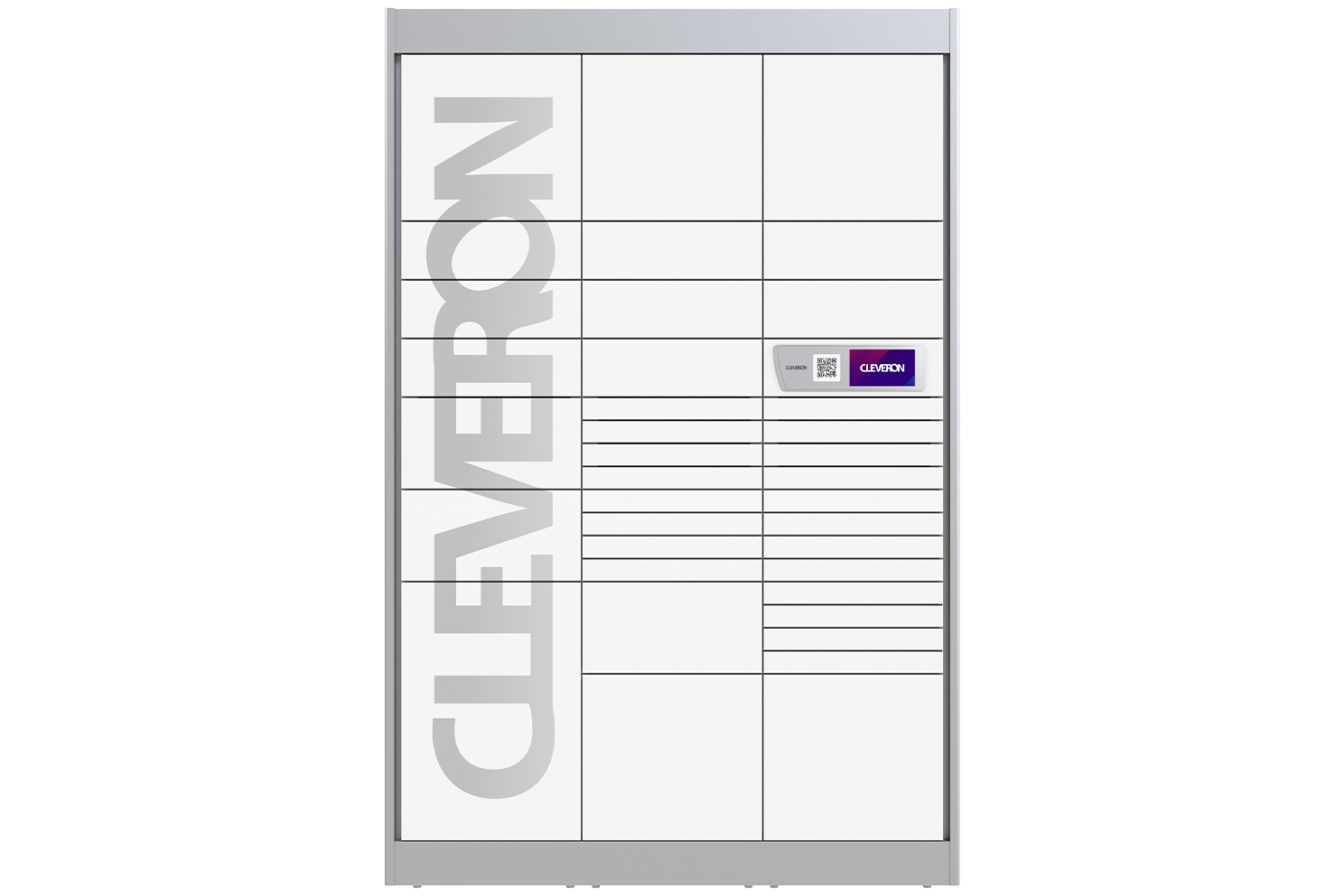

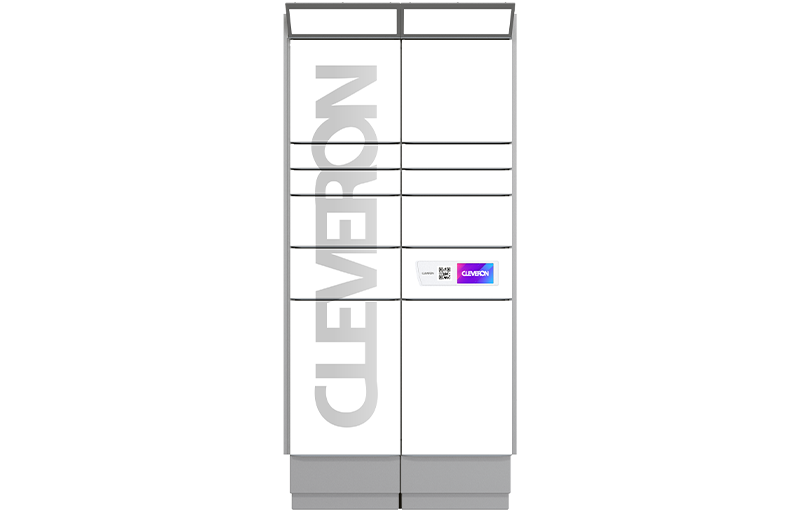

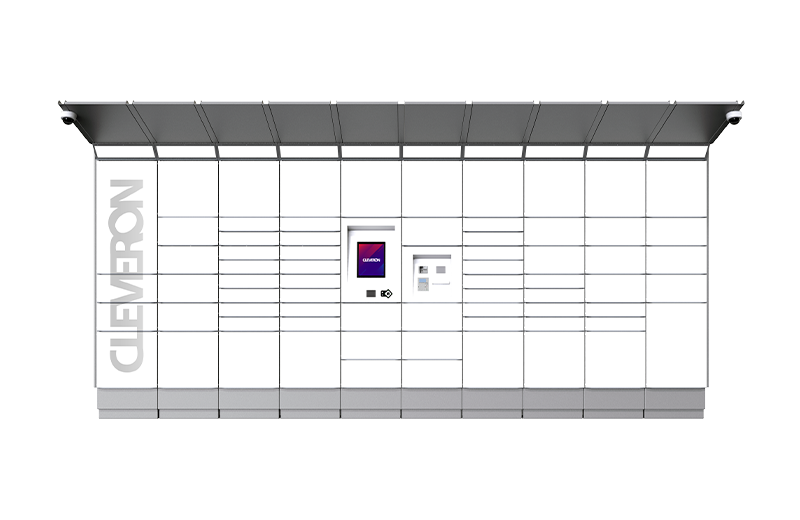

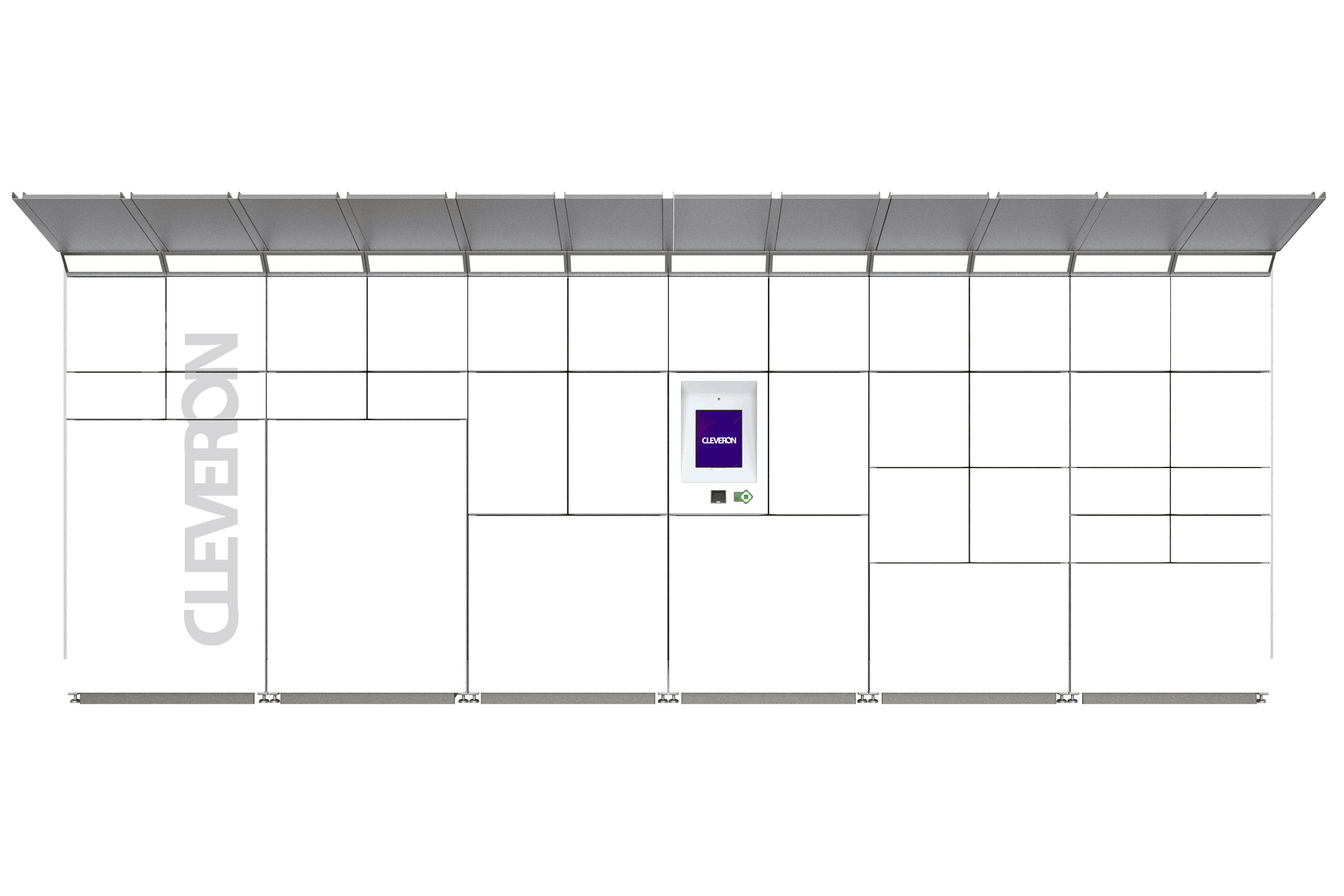

- Scale fails: A dedicated employee can manually process approximately 50 parcels per day. Our robotic solutions, like automated parcel lockers, can easily handle 10 times that volume, instantly improving your logistics capacity.

Having automated solutions is the only way to scale with modern e-commerce demand. But the technology is only as good as the operational support behind it.

We recently hosted an expert panel discussion with our industry leaders – Mark Schneider (Business Development Director UK), Taavi Ojandu (Service and Operations Manager), and Siim Nopri (Sales and Business Operations Head), who dove deep into the frenzy of retail logistics during Black Friday.

This session explored everything from broad industry trends and operational challenges to customer-facing pain points, highlighting precisely how Cleveron’s automation solutions strengthen resilience, scalability, and customer experiences during the busiest season of the year.

Cleveron’s 8-Point guarantee for peak season readiness

For more than a decade, Cleveron has been refining its strategy to ensure that our automated units not only survive the peak but also thrive. Our entire preparation process is framed as an “8-Point Guarantee,” designed to protect your revenue, staff, and customer satisfaction during the most critical weeks of the year.

1. Data-driven readiness

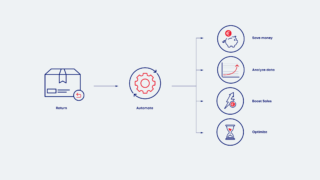

Our readiness starts months in advance and is driven by data analytics. We dive deep into incident logs, parcel volumes, and customer behaviour from past years, working specifically with data to identify key trends and vulnerabilities.

This enables us to predict potential bottlenecks and allocate resources with precision before the first viral sale occurs.

This proactive approach ensures we’re never guessing, we’re forecasting and countering issues long before they appear.

Taavi Ojandu, our Service and Operations Manager, highlighted the value of this approach in the recent webinar:

“We collect lessons identified and lessons learned. By comparing incident and parcel data from past years, we can better forecast and counter issues before they appear.”

2. Training your team to be fully prepared

In the lead-up to the holiday surge, our focus shifts to minimising risk.

We conduct annual, proactive maintenance and ensure that all our customer and internal technicians receives comprehensive refresher training. This ensures two vital outcomes:

- Mechanical integrity: Every unit is functioning smoothly at maximum capacity.

- Operational confidence: Your in-store staff is fully prepared to handle the machines – loading the parcels and referring to localised training books or us when they have questions.

3. We fix it before you know it

Our 24/7 remote monitoring team is on full alert. Automated, real-time alerts notify our engineers of potential issues, often before your in-store team is even aware that a problem exists.

“We are more proactive about it. When we can monitor with more resources, then we can we can even maybe avoid some issues before they happen,”

– Said Siim Nopri, Head of sales and business operations, on our recent panel discussion.

Most retailers wait for a customer complaint before calling their logistics provider. Our customers, however, get a call from us saying, “We’ve just resolved a minor glitch remotely.“ That’s the power of proactive, 24/7 remote issue resolution.

4. We elevate service levels temporarily

During peak season, every minute of potential downtime represents lost revenue and a frustrated customer. We temporarily elevate our service commitment to protect your sales velocity.

Taavi Ojandu, our Service and Operations Manager, recently pointed out on the panel discussion: “If a technician usually arrives within 12 hours, during peak season, that can be 6 hours even. It’s about reacting faster because store activity and customer pressure are so much higher.”

Taavi continued – “The other part of the SLA (service level agreement) is maybe having a dispatch team ready, somebody who can assign technicians even on weekends, for example, on Saturday, Sunday, to have somebody on the technician side as well as a manager available to coordinate the help desk if needed.”

We ensure our technicians and Service Partners are available 7 days a week, with all escalation contacts confirmed weeks in advance.

5. We prioritise critical incidents

When the pressure is highest, we focus our entire operational capacity exclusively on critical incidents, situations where an automated locker or unit is fully unavailable.

“The focus is mostly on critical incidents where the units are fully impacted and not usable. So we redesigned our dashboards, our priorities.”

– Taavi Ojandu mentioned.

Less time-sensitive work, such as long-term installations, is temporarily postponed. This allows us to dedicate 100% of our technical focus to keeping your core revenue stream operational.

6. Coordinating with our partners

Peak season presents a global challenge, and our support network is accordingly planned. We work closely with our international Service Partners well in advance to align availability and escalation matrices. The goal is simple: the retailer doesn’t need to worry about local resources.

“We start preparing our service partners in summer, aligning on where sales will peak, who’s available, and how to manage escalations.” –

Taavi Ojandu added.

Our global readiness ensures a technician will be available in Berlin or Sydney just as quickly and reliably as they are at our home base.

7. Strategic inventory management

A failure is inevitable; a delay is optional.

We constantly monitor the components used frequently across our entire network and proactively raise stock levels for critical, fast-moving items before the surge.

This preparation moves the required spare parts closer to your operational region based on predictive failure models. This way, we’re ready to react immediately when an issue appears.

8. We prepare you with the proven data

Beyond our own processes, we empower you with data. We share actionable insights on parcel size trends, locker usage data, and service analysis.

“Data is hugely important… It can also help shift customer behaviour, which enables clients to dictate when they come to collect parcels, when they place orders, and how long they stay. We can look at the parcel sizes that are coming through, and we can predict what resources are needed and how that resource is allocated.”

– Mentions Mark Schneider on our recent panel discussion.

This enables your operational teams to clearly understand when and where to expect spikes in demand. You can then adjust staffing schedules, internal promotions, and inventory distribution with surgical precision, ensuring you maximise every available hour of peak traffic.

The truth about being “Ready”

We understand that automation can seem daunting, especially with legacy systems, but as our industry leaders emphasise, claiming you are “not ready” is to accept the inherent risk of lower delivery efficiency, operational bottlenecks, and employee burnout. Automation isn’t an optional upgrade; it’s the new staple of modern logistics.

For those new to the game, you have a distinct advantage: you can design hyper-efficient processes from day one, skipping the costly legacy phase entirely. For everyone else, the key is to start small.

Identify your biggest pain point and automate just that piece first, then scale up as you become comfortable. Automation is not a future goal; it’s the foundational commitment to sustained peak performance.

To know how we can help you get started, reach out to our team today.